Description for the Screw Conveyor.

Overview

- Long-lasting, easy to maintain screw conveyors are used for the dust-free,horizontal, inclined and vertical transport of fine-grained and floury materials.

- Suitable adaptations are made to handle coarse-grained, higher temperature, abrasive or poorly flowing materials.

- Screw conveyors also offer the option of multiple inlets and outlets.

- Various versions handle not only the transport of bulk materials but also emptying, metering, loading, screening and mixing

SALIENT FEATURES:-

- The conveyor trough in trough screw conveyors is manufactured as a torsionally rigid sheet metal housing made of standard section lengths with connecting flanges, to which are bolted sturdy cover plates.

- There is also an inspection flap above the Casings, Drive Unit & Driven Unit.

- Abrasive materials can be handled by using manganese alloy steel, hard surface welding, fusion-cast basalt linings or material padding.

- Split end walls are bolted to the ends of the trough. This makes it easy to dismount the screw shaft once the metal cover plates have been removed.

- Intermediate supports are only required about every 6 meters. They are supplied loose for mounting during assembly.

Ø The shaft exit points are usually sealed by gray cast iron stuffing boxes.

- The screw shaft is designed as a solid shaft or a rigid tubular shaft with integrated end journals and a welded-on screw thread.

Ø The end bearings are pedestal bearings with antifriction-bearing inserts.

Ø When a screw shaft requires intermediate bearings for longer conveying distances. These are designed as easily replaceable units, the torque is transmitted by bolted couplings.

- We supply a plain bearing as standard with replaceable two-part, gray cast iron bearing shells. They can be set up for grease gun or central lubrication according to the operational conditions

- On request, we also supply antifriction bearings with split roller bearings in a sealed, grease-filled suspended housing.

- The drive comprises a standard geared motor unit.

Classification of Screw Conveyor :-

- On the basis of Conveying Direction:-

- Right Hand Spiral

- Left Hand Spiral

- On the basis Of Trough Type:-

- U Type

- Tubular Type..

- V Type

- On the basis of Flight Type:-

- Full Thread

- Band Thread

- Paddle Thread

- On the basis of Shaft Type:-

- Solid Shaft

- Tubular (Hollow) Shaft

Screw Conveyor Specification

Advantages:-

- Independent Material reception

- Excessive Feeding

- Low Maintenance

- High temperature resistant ( up to 450?C )

- More than 1 inlet and Outlet possible

- Because of closed trough easy fulfillment of safety regulations and environment protection. ( Dust & Dust Proof )

|

Equipment |

Screw Conveyor |

|

|

Specification |

Range |

|

|

FROM |

TO |

|

|

Capacity (TPH) |

5 |

500 |

|

Temperature (?C) |

0 |

450 |

|

Bulk density (T/cubic meter) |

0.1 |

1.6 |

|

Moister(%) |

0 |

20 |

|

Width (mm) |

200 |

2000 |

|

Length (mtr) |

up to 60 |

|

Screw Conveyor Applications

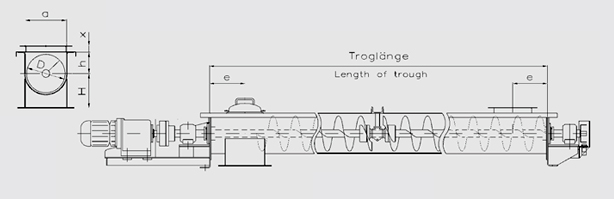

Trough-Type Screw Conveyor

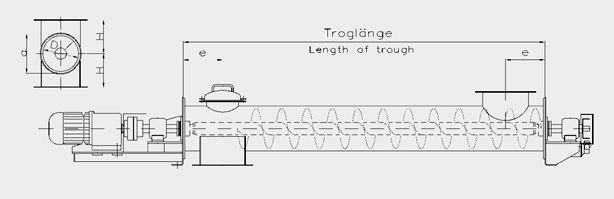

Tubular Type Screw Conveyor

Click here for more detials

We also recommend you bellow products