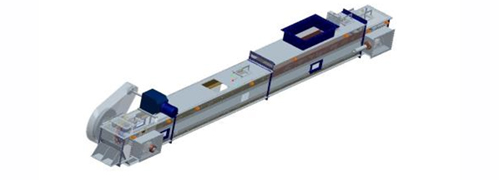

Description for the Non Pressurized Drag Chain Feeder .

Overview:

- Mechanical continuous conveyors, where material to be conveyed is moved inside a closed trough by a “Traction mechanism” with extended flights.

- Traction or Tractive force is the force used to generate motion between a body and a tangential surface, generally through the use of Dry Friction.

- The Dragging action of Link conveys the material at the required location.

- Drag Chain Conveyors are suitable for the Dust-free, Horizontal and Inclined conveying and metering of even the coarsest types of bulk materials. Available as Single Strand and Double Strand Conveyors.

Salient Features:-

- Special chain retainer to prevent material to buildup and thus the chain climbing

- Easily dismounting System for maintenance

- Robust in construction

- Available with world class quality RUD Forky chain

- Special Mn alloy steel liner for abrasive material

- Available with auto-tensioning unit.

- Designed to sustain pressure up to 2000 mmWC.

Advantages :

- Independent Material reception

- Excessive Feeding

- Low Maintenance

- High temperature resistant ( up to 1200?C )

- More than 1 inlet and Outlet possible

- Because of closed trough easy fulfillment of safety regulations and environment protection. ( Dust & Dust Proof )

Non Pressurized Drag Chain Feeder Specification

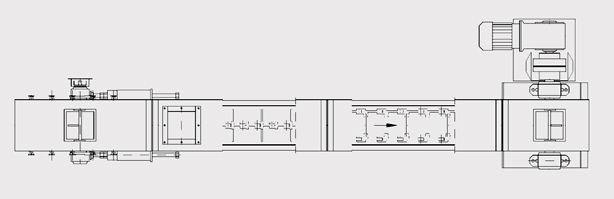

Types Of Feeder :-

- Single Strand :- Forged Link is present at Centre.

- Double Strand :- When 2 side Forged Links are present.

Based On Conveying Direction :-

- Horizontal

- Ascending

- Horizontal + Ascending

- Horizontal + Vertical

- Horizontal + Ascending + Horizontal

|

Equipment |

Non Pressurized Drag Chain Feeder |

|

|

Specification |

Range |

|

|

FROM |

TO |

|

|

Capacity (TPH) |

1.5 |

200 |

|

Temperature (?C) |

0 |

300 |

|

Bulk density (T/cubic meter) |

0.1 |

2 |

|

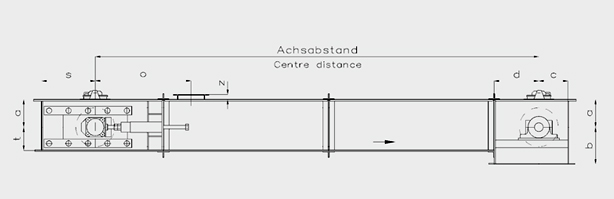

Length (mtr) |

1 |

100 |

|

Width (mm) |

200 |

2000 |

|

Moister (%) |

0 |

20 |

Non Pressurized Drag Chain Feeder Applications

Einstrang Single Strand

Dopplestrang Double Strand

Click here for more detials